Description

CONCENTRATED ACETONE CONCRETE DYE / POLISHING POWDER

Beautifully and easily color concrete in 20 awesome colors. Interior Kolour Dye is a deep penetrating, translucent, powdered color dye for staining all types of interior concrete. These dyes come in a concentrated, ultra-fine powder form that you mix with acetone to create a ready to use product in the intensity of your choice. Interior Kolour Dye can be used as part of a polishing process or in a standard dye and seal application.

Acetone Dyes are now the preferred method for coloring concrete, especially interior concrete floors. Dyes create consistent predictable colors every time, without the mess and labor associated with old-fashioned acid staining. With acetone dyes, floors can now be prepped, stained and sealed in a single day. Pick the perfect color, or mix and match to create the exact look, color and contrast you desire.

Interior Kolour Dye can be used for all types of indoor projects such as; residential floors, commercial floors, garage floors, restaurants, showrooms and many other types of interior decorative concrete.

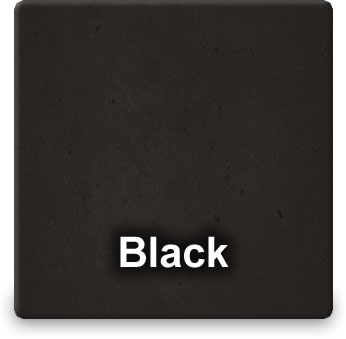

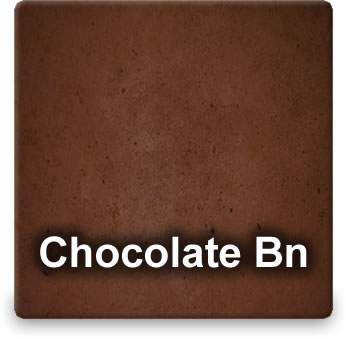

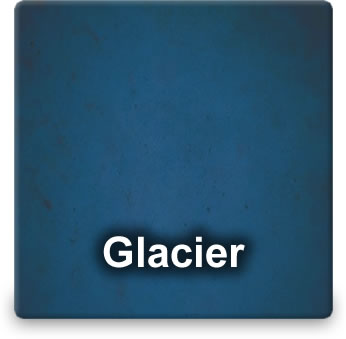

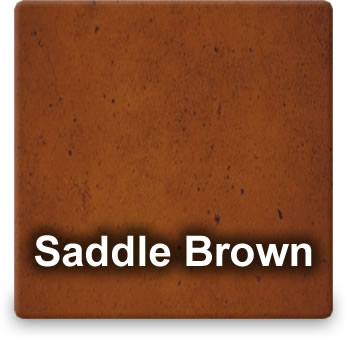

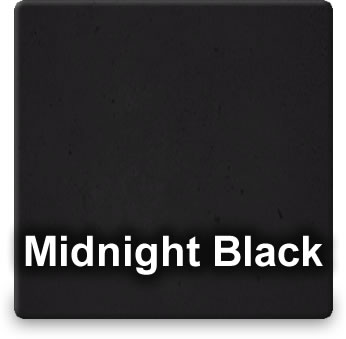

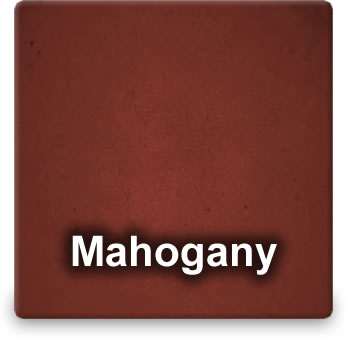

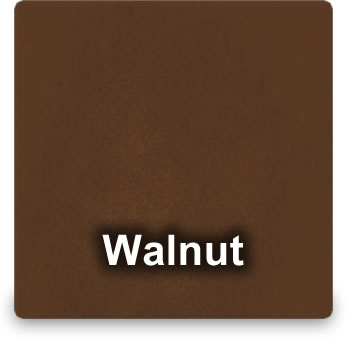

Acetone Polishing Dye is available in 20 awesome colors:

Not sure which color is right for you?

Our Interior Kolour Dye sample sizes make it easy to choose! Sample sizes come pre-measured and ready for you to mix with acetone!

Essentials

- Concentrated Powder Dye

- Mixes with acetone

- 20 awesome colors

- Interior use only

- May be polished or sealed

- Spray Application

- Coverage - See Detailed Info

Detailed Info!

To learn more, keep reading or click a link below to jump to a specific topic:

- Detailed Description

- Cleaning and Preparation Instructions

- Mixing

- Application Instructions

- Maintenance

- FAQ's

Interior Acetone Dye / Polishing Powder

Acetone dyes are the new generation of concrete coloring products. These dyes are extremely easy to use and allow a floor staining project to now be completed in hours instead of days! Dyes are available in a huge selection of colors that can be mixed, mottled and layered to create an endless array of color and contrast options. Interior Kolour Dye comes in a concentrated powder form that is supposed to be mixed with 1 gallon of acetone, but due to it's super-high concentration we often recommend mixing each bottle with 2 gallons of acetone. This not only saves money, it makes the dye much easier to apply. After application, powdered dyes should be polished or sealed to enhance and protect the color. Dyes should only be sealed with "film-forming" sealers which will physically "lock" in the color.

One unique challenge with acetone dye (especially on smooth interior floors) is that rolling a sealer (especially solvent-based sealers) over the dyed concrete will dissolve and lift the dye onto the roller, distorting the color and pattern you worked to create. Because of this, we always recommend that if possible the first coat of sealer or a primer is sprayed onto the dyed surface, not rolled. Of course, this should be the preferred method anyway since it is faster, easier and creates a more even and uniform coat. This first "primer" coat will lock in the dye, making it safe to proceed with the top-coat of your choice. Dyed concrete is compatible with all types of sealers and coatings, from simple inexpensive acrylics, to high performance urethanes and polyaspartics. Be sure to choose the sealer or sealers that are right for your project and the use it will receive. If you need help, give us a call and we'll be glad to walk through the process with you. That's what we're here for!

Cleaning and Preparation Instructions

3. If polishing: Apply Interior Kolour Dye after polishing with 400 grit resin.

If sealing: Diamond grind floors to between 50 - 100 grit. Be sure to remove all swirl marks, but do not grind finer than 100 grit. Beyond 100 grit, topcoat adhesion will be compromised.

4. Allow area to dry completely before dye application.

Mixing Instructions

WARNING: Follow the acetone manufacturer's instructions and the material safety data sheet (Safety Data Sheet) for exposure limitations and safe handling practices. Acetone is HIGHLY FLAMMABLE! Do not smoke! Turn off all portable heaters and gas pilot lights. Extinguish all open flames prior to use! Avoid sparks!

Interior Kolour Dye is packaged in a powdered concentrate form which needs to be mixed with acetone. Mix each bottle of Interior Kolour Dye into appropriate amount of acetone to create the concentration and intensity desired. Each bottle should be mixed with a minimum of 1 gallon of acetone, but most contractors prefer further dilution to make a less concentrated dye. This will make the dye much easier to apply. We recommend a typical dilution of 1 bottle of concentrate : 2 gallons of acetone. Using the re-closable acetone container is recommended for mixing. Blend the mixture by stirring the open container, or by shaking the closed container for 30 seconds. After mixing, allow powder to dissolve for a minimum of 3 hours before use. Do not use any form of electrical equipment to mix the dye with the acetone!

Application Instructions

Before application, always test the dye in an inconspicuous area to ensure color and compatibility are acceptable. If you plan to apply a sealer, apply a small amount of water to the test area, observing the color while wet. This will approximate the sealed color (if using a color enhancing sealer). Concrete should be fully cured for 28 days before dyeing or sealing.

Perform moisture vapor test by taping a plastic sheet on a one square foot section of floor. Remove plastic the following day. If floor is wet, DO NOT PROCEED. First determine if moisture is remaining from the cleaning process, or if it is a more serious issue coming from the soil below the slab. If you suspect a moisture issue from beneath the slab, DO NOT PROCEED.

Protect all areas not to be stained. Mask off all adjacent surfaces. Use coated cardboard as a spray shield. Use only acetone resistant sprayers. Before opening or handling acetone and Kolour Dye, first put on proper protective equipment including eye protection, rubber gloves and respirator rated for use with acetone.

Surfkoat Kolour Dye may be diluted with additional acetone to create lighter colors if desired.

Multiple colors of Kolour Dye may be used to create any desired combination of colors, highlights and contrast. If using multiple colors, always start with the lightest color first as a base coat.

Coverage Rates:

Coverage rates are approximate and will vary depending on substrate density, porosity and application.

Trowelled Concrete: One container of Kolour Dye concentrate is typically enough to color 500 - 600 sq. ft. of troweled concrete.

If diluted with 2 gallons of acetone: Apply to concrete at a rate of 250 - 300 sq. ft. / gallon.

If diluted with 1 gallon of acetone: Apply to concrete at a rate of 500 - 600 sq. ft. / gallon

If polishing: Apply Interior Kolour Dye after polishing with 400 grit resin.

If Sealing: Allow Kolour Dye to dry for approximately 30 minutes prior to applying sealer or protective coating. If using a solvent-based sealer, the first coat of sealer or "primer" should be sprayed over the dyed surface, not rolled. Rolling may reactivate the dye and cause it to lift onto the roller.

You have many choices when it comes to choosing a sealer. Several factors including budget, durability and desired appearance will influence this decision. To give you a starting point, here are our most popular recommendations:

Interior Floors - High Performance:

First Coat (primer coat):

Polyrez 6000 WB Urethane (for enhanced color)

Polyrez 1040 WB Epoxy (for minimal enhancement)

Second Coat (topcoat):

Polyrez 6000 WB Urethane (for a gloss finish)

Polyrez 6100 WB Matte Urethane (for a matte finish)

Interior Floors - Economical:

Be sure to choose the appropriate sealer for your application. If you need help, check out the "Help Center" or just give us a call and we'll be glad to walk through the process with you. That's what we're here for!

Of course, having the right tools will make your job easier, so scroll to the bottom to see our recommended Sprayers, Brushes and Application Tools!

Maintenance

Maintain protective top-coat according to manufacturers recommendations.

FAQ's

Got Questions?

Check out the "Help Center", send us an email or just give us a call and we'll be glad to help you with your order!