Description

CONCRETE COATING REMOVAL TOOL

The Mastic / Coating Removal Tool is a rigid, aggressive, 25 grit diamond grinding tool for use on smooth concrete floors. This tool easily removes mastic, adhesives, thin-set and most thin-mil coatings like paint or urethane. Typical blade life of the Mastic Removal Tool averages between 5000-10,000 sq. ft. Wet-grinding is always recommended if possible, as water will keep the diamonds cooler and substantially increase their life. The Mastic Removal Tool is available in 12"-20" sizes, and with 5,6,8 or 10 blades, depending on the diameter chosen.

The Diamabrush system is an extremely affordable and effective way to prepare and profile concrete floors for the application of dye, stain, sealer and epoxy. These tools are easy to use, require no special training and fit most all standard floor machines available at most rental stores.

The Diamabrush Mastic Tool is also available for rent at most Home Depot locations across the country. Although we would love to sell you a tool of your own, we know that buying a tool outright is not the right choice for everyone. If you only have a small project or just need the tool for a one time use, renting is a great way to go. The most important thing is that you get your floor prepped properly for your staining, sealing or coating project.

To ensure the tool you order is a perfect fit for your specific machine and set-up, we custom build each tool per order. This allows us to ship most Diamabrush orders NEXT DAY, and of course shipping is always free to most states!

Above are two excellent videos explaining how the removal tool works and how to use it most effectively. The first one is actually a training video made specifically for associates in the Home Depot rental department.

Essentials

- Removes Coatings

- Removes Mastic

- Removes Thin-Set

- Rigid 25 grit Blades

- Available in 12"-20" Sizes

- Available with 5,6,8 or 10 Blades

- Clockwise or Counter-clockwise

- Custom Fit to Your Machine

Selecting The Right Tool

When ordering your new Mastic / Coating Removal Tool you will need to know several things about the machine you will be using the tool on.

1. What is the make and model number of the machine the tool will be used on?

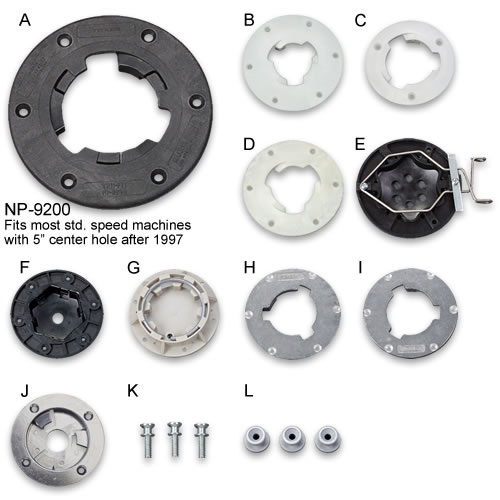

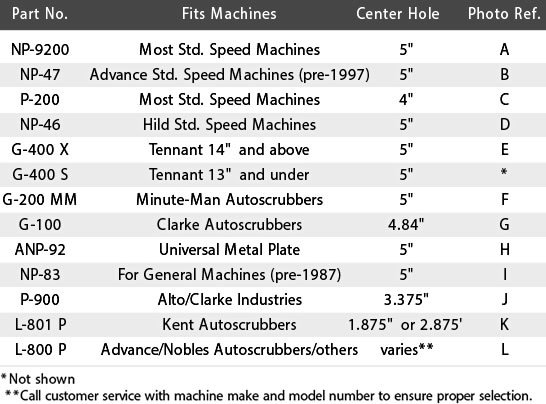

Once you have this information, open the Machine Reference Guide above. The machine manufacturers are listed in alphabetical order. Once your brand of machine is found, continue down until you find the correct model. By reading across, you can then determine the correct clutch plate required for your specific machine. Disregard the "brush sizes" and "pad driver sizes listed in the reference guide, they are for other applications. If possible, please include your machine make and model in the "Machine Make / Model" section of the order form. This is not required, but it is very helpful to our technicians when assembling your new tool.

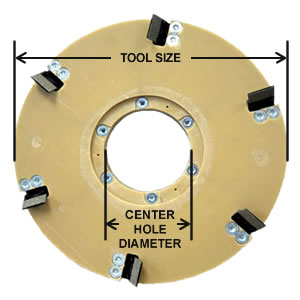

2. What diameter tool do you need?

For most Diamabrush applications, the tool block diameter should be ordered 2" smaller than the stated machine size if you wish for the tool to fit up inside the housing of the machine. If you wish for your new tool to extend all the way to the edge of your machine housing, you will need a riser to allow the desired diameter tool to drop below the housing and extend outwards toward or past the edge of the machine housing. A riser is a just a simple spacer that is mounted between the clutch plate and tool. You will have the option of including a riser when you select your required clutch plate.

Either way is acceptable and there are pros and cons to each. A tool that fits up inside the machine housing, without a riser allows for a lower center of gravity and also makes the tool much less vulnerable to damage. On the other hand, a riser allows for a larger tool that will cover more area and allows you to grind all the way up against walls and other stationary objects. We usually recommend ordering your tool 2 inches smaller than the stated size of your machine and installing it without a riser, but the choice is up to you to decide which setup is best for your application. If you do choose to use a riser and order a larger tool, be very careful not to allow the diamond blades to impact stationary objects.

3. What is the rotation of your machine?

The Mastic / Coating Removal Tool is available in both clockwise and counter-clockwise rotations. Machine rotation is easily determined by looking straight down at the machine as it sits on the floor, and simply noting the direction of rotation. The majority of machines on the market today have a counter-clockwise rotation. If the Machine Reference Guide specifies the standard NP-9200 clutch plate for your machine, then it is a counter-clockwise rotation. If the Machine Reference Guide specifies a different clutch plate for your machine, you will need to determine the direction of rotation.

4. What center hole diameter is required?

Diamabrush Tools are available with a variety of different diameter center holes, as well as with no hole at all. Once again, the specifications for center hole sizes can be found in the Machine Reference Guide. The majority of machines on the market today require a standard 5" diameter center hole for mounting of the standard NP-9200 clutch plate. If you need a different, or specific size center hole, or desire a solid tool with no center hole, be sure to include that information in the "Additional Tool Notes" section of the order form.

Not sure which tool you need?

Just give us a call with the make and model of your machine, and we'll be glad to help!

Got Questions?

Check out the "Help Center", send us an email or just give us a call and we'll be glad to help you with your order!