Description

100 GRIT DIAMOND POLISHING TOOL

The 100 grit Black Polymer Tool is the 2nd step in the Diamabrush concrete polishing process. This tool can also be used to scuff / sand existing coatings before re-coating.

Typical blade life of the 100 grit Polymer Tool averages 60,000 sq. ft. or more. Always use the polymer tools with water. Using the polymer tools dry will quickly destroy the blades. These tools also must be conditioned by soaking in water for 72 hours before use. This conditioning will prevent the blades from being brittle and reduce the chance of breakage. All polymer blade tools are available in 12"-20" sizes. All grits of polymer blades are multi-directional and can be operated clockwise or counter-clockwise.

The Diamabrush system is an extremely affordable and effective way to prepare, profile or polish concrete floors. These tools are easy to use, require no special training and fit most all standard floor machines available at most rental stores.

To ensure the tool you order is a perfect fit for your specific machine and set-up, we custom build each tool per order. This allows us to ship most Diamabrush orders NEXT DAY, and of course shipping is always free to most states!

Above are two excellent videos explaining both the Diamabrush re-coat and polishing processes. The first video addresses how to properly prepare an existing coating for re-coat. The second video is an in-depth explanation of the polishing process and each of the successive polishing steps

Essentials

- Flexible 100 grit Blades

- Sands Coatings for Re-coat

- 2nd Polishing Step

- Available in 12"-20" Sizes

- Blades are Multi-Directional

- Custom Fit to Your Machine

Selecting The Right Tool

When ordering your new Polymer Polishing Tools you will need to know several things about the machine you will be using the tool on.

1. What is the make and model number of the machine the tool will be used on?

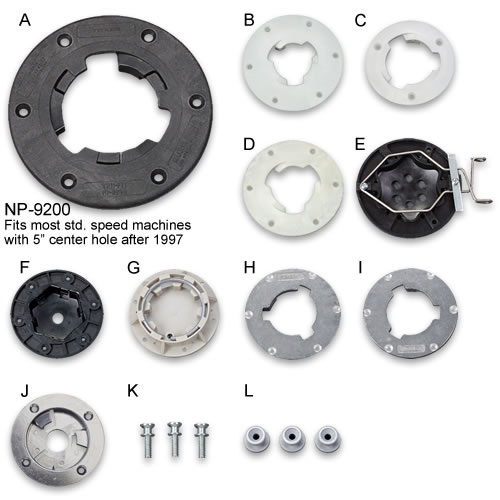

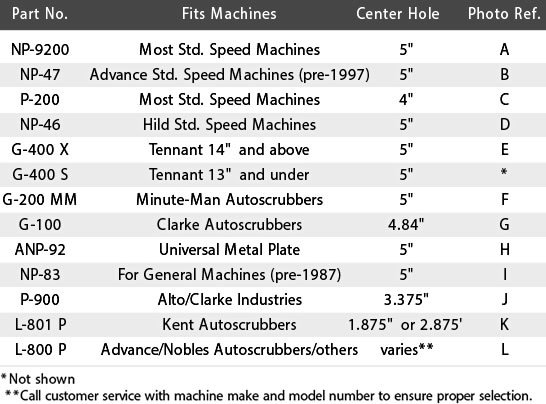

Once you have this information, open the Machine Reference Guide above. The machine manufacturers are listed in alphabetical order. Once your brand of machine is found, continue down until you find the correct model. By reading across, you can then determine the correct clutch plate required for your specific machine. Disregard the "brush sizes" and "pad driver sizes listed in the reference guide, they are for other applications. If possible, please include your machine make and model in the "Machine Make / Model" section of the order form. This is not required, but it is very helpful to our technicians when assembling your new tool.

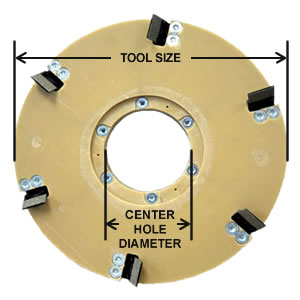

2. What diameter tool do you need?

For most Diamabrush applications, the tool block diameter should be ordered 2" smaller than the stated machine size if you wish for the tool to fit up inside the housing of the machine. If you wish for your new tool to extend all the way to the edge of your machine housing, you will need a riser to allow the desired diameter tool to drop below the housing and extend outwards toward or past the edge of the machine housing. A riser is a just a simple spacer that is mounted between the clutch plate and tool. You will have the option of including a riser when you select your required clutch plate.

Either way is acceptable and there are pros and cons to each. A tool that fits up inside the machine housing, without a riser allows for a lower center of gravity and also makes the tool much less vulnerable to damage. On the other hand, a riser allows for a larger tool that will cover more area and allows you to grind all the way up against walls and other stationary objects. We usually recommend ordering your tool 2 inches smaller than the stated size of your machine and installing it without a riser, but the choice is up to you to decide which setup is best for your application. If you do choose to use a riser and order a larger tool, be very careful not to allow the diamond blades to impact stationary objects.

4. What center hole diameter is required?

Diamabrush Tools are available with a variety of different diameter center holes, as well as with no hole at all. Once again, the specifications for center hole sizes can be found in the Machine Reference Guide. The majority of machines on the market today require a standard 5" diameter center hole for mounting of the standard NP-9200 clutch plate. If you need a different, or specific size center hole, or desire a solid tool with no center hole, be sure to include that information in the "Additional Tool Notes" section of the order form.

Just give us a call with the make and model of your machine, and we'll be glad to help!

Got Questions?

Check out the "Help Center", send us an email or just give us a call and we'll be glad to help you with your order!